|

|

|

Last Changed 3/23/2009

|

Loose wheel lug nuts create a very dangerous condition. There is

the extreme chance that if driven long enough, the lug nuts could

come off of the hub studs and the wheel rim could come off the

axle. More likely, the wheel rim, loose on the hub, will wear the

hub studs, causing them to fail. Tight lug nuts is especially

important to trailer where the wheels are subjected to more

side loads from turns during parking.

Aside from the risk of loosing a wheel, the probable outcome of the

wheel rim being loose on the hub, is a lot more flexing of the tire

carcass, causing heat and breakdown of the tire.

No matter the result, loose lug nuts is a very bad condition. There

is a lot of misunderstanding about torque and wheel lug nuts.

Many believe that if the lugs nuts are loose, then enough torque was

not applied to the lug nuts. This is not true. In fact, over

torqueing can be part of the reason for the loose lug nuts. More

importantly, over torqueing lug nuts can over stretch the hub studs and

lead to the failure of the studs.

|

|

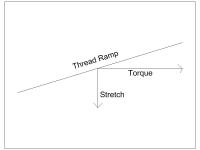

First a little background. The threads on the hub stud and in the

lug nut are actually ramps wrapped around in a circle. When torque

(twisting force) is applied to the lug nut, the rising of the ramp

causes the stud to be stretched. This stretch is what causes the

lug nuts to stay tight. The stretched stud is like a spring and

pulls the nut towards the hub holding the wheel rim tight. |

Wheel hub types

There are basically two types of wheel hubs determined by how the wheel is centered on the hub.

|

|

Stud piloted wheels have tapered stud holes

and the lug nuts have a matching taper. The centering of

each lug nut in the stud hole of the wheel will cause the

wheel to be centered on the hub. The hub hole in the wheel

only serves to allow hub clearance. |

|

Hub piloted wheels use the center hole of

the wheel to fit over the matching size ridge on the hub.

The wheel is centered on the hub by the hub hole. The lug

nuts will have a flush face in contact with the wheel. The

lug nuts only secure the wheel to the hub.

Since the hub piloted wheels use the hole for centering the

wheel, the lug nuts only have to hold the wheels tight. |

Click on images to enlarge |

|

Hub Piloted Wheel (lower example):

The wheel hub hole and the centering ridge of the hub mate

and the wheel is centered. the stud nuts only have to hold

the wheel against the hub.

Therefore, the best thing for hub piloted wheels is to

re-torque the lug nuts after a few miles of travel. Once

should be enough. |

|

Hub Piloted Wheel (upper two examples):

Stud piloted wheels have a greater opportunity to not being

centered when first put on. There are 5-8 studs and all of

them have to be centered for the wheel to be settled. In an

ideal situation, when you first put the wheel on, the lug

nuts should be finger tight and then spin the wheel to allow

it to settle. This is also why you should apply torque to

the lug nuts in a star pattern as that helps the wheel to

settle. |

|

In reality, especially with the weight of the wheels we have on our

RVs, you will probably have to use a wrench just to get the lug

nuts seated and spinning the wheel will probably be out of the

question.

The chance of a lug nut not being fully seated could result in a

condition like the center drawing in the picture above. You can

apply full torque and the nut will not seat. You can over torque

the lug nuts and still not seat the lug nut that is off center.

Again, driving down the road will allow the wheel to settle. Again,

the best thing is to torque the lug nuts, drive a bit, and re-torque

the lug nuts. A couple of times would be appropriate for stud

piloted wheels.

When I was in the ARMY, I saw truck drivers use a three foot breaker

bar and stand on the bar to torque the lug nuts on a truck (several

hundred pounds of torque) and fail inspection the next day with

loose lug nuts. I would use the torque wrench, drive the truck down

the runway, and re-torque until the nuts were found to not be

loose. After that, the nuts stayed tight until the next time the

wheel needed to be removed.

Over torqueing is done every day on wheel studs. Each size stud has

an appropriate torque. That torque will stretch the stud the amount

necessary to keep the lug nut from turning.

If you over torque, you over stretch the stud and weaken it.

Even using a torque wrench you can over-torque a stud. Once a lug

nut has reached the proper torque, if you use the torque wrench

again, the clicking action of a snap torque wrench will apply a

slight amount of over-torque. Click enough times and you are

over-torqueing the stud. So the next time you see a mechanic using a

air/electric power nut driver, and he applies power until the

clicking limit is reached several times, you just watched a stud

being stretched.

There are torque wrenches that use a bending indicator that do not

increase the torque when you check the torque level. The snap torque

wrenches work without your having to look at it when torqueing. The

objective is to torque the lug nut until the wrench snaps. One snap

is enough.

Lubricating the Threads

Some people like to put lubricant on the threads so that they are

easier to remove. You actually make things worse doing that. With

lubricant on the threads, you can put more stretch into the stud

with the same amount of torque. The lubricant will eventually

evaporate and when you go to remove the lug nut, you have the extra

stretch tension to break loose.

Likewise, if the threads are cruddy, that can induce more friction

and cause the stud to not be properly stretched.

When torque values are given, they are for dry threads.

Torque Values

| Sample Torque Values |

| Stud Size | Torque |

| 3/8" (fine) | 35-45

lbs.-ft. |

| 7/16" - 18 (fine) |

50-60 lbs.-ft. |

| 12 mm - 1.5 (fine) |

70-80 lbs.-ft. |

| 1/2" - 20 (fine) |

80-90 lbs.-ft. |

| 5/8" - 18 (fine) |

110-125 lbs.-ft. |

| 5/8" - 13 (course) |

110-125 lbs.-ft. |

|